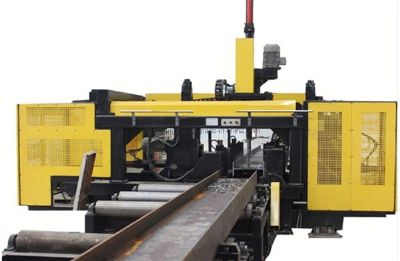

Heavy Structural Fabrication 3d Drilling Machine For H Beam

SteelProduct DescriptionThe CNC 3D drilling machine has three

independent drilling power heads, namely vertical, left and right

drilling heads. Each drilling power head contains two CNC axis

drives and a digital hydraulic feed drive perpendicular to the

workpiece direction. The drill bit and the main shaft are connected

by a quick-change drill sleeve, so that the drill bit can be

replaced quickly and accurately. Each drill bit can be independent

and can complete the drilling operation at the same time. After a

successful automatic clamping, all holes in the hole group can be

processed.Product

Parameters ModelSWZ1000SWZ1250WorkpieceSizeH- beam (web plate

height x flange width)Max.1000 x 5001250 x 600Min.150 x

75Length(mm)≥2000Max. Thickness(mm)80Drilling DiameterVertical

DrillingØ12-Ø33.5Horizontal DrillingØ12-Ø26.5Spindle UnitsQty. Of

SpindleOne spindle on each side( top, left,right) Total 3

spindlesRotation Speed (rpm)120-560Spindle Motor Power (kw)3 x

4kwMax. Feeding Stroke(mm)Left & Right 140Vertical:325Feeding

Speed(mm/min)20-300Movement of left/right spindle(mm)In the

direction of workpiece length:520Above the vertical

base-level:30-470Above the vertical base-level:30-570Movement of

top spindle(mm)In the direction of workpiece length:520Beyond

horizontal base-level:45-910Beyond horizontal

base-level:45-1160MarkingCharacter Qty.36Character SizeØ10Overall

Dimension(L x W x H) mmAprox.4550 x 3050x 3520Aprox.4800 x 3050

x3520Total Power(KW)34kwMachine Weight(Kg)7000Kg8000KgFeature1.

Equipped with three drilling units, three drilling units can drill

holes simultaneously and adopt self-controlled stroke drilling

head. 2. No need to set thickness of work piece and length of

drill bits, it will do fact-feeding or feeding automatically by

sensor signal, and with high efficiency. 3. Frame made of

sturdy electro-welded and normalized Plates and Square Beams. The

structure with roller guides on which the sliders supporting the

three spindles guarantees the total moving stability, and ensures

the working precision;4. This machine can read AUTOCAD drawings and

lofting software files automatically, such as DXF, NC1.5. Equipped

with automatic lubrication system and air conditioner for electric

cabinet. 6. Equipped with automatic feeding systems, which

will clamp and feed material into machine automatically.7. PLC

systems, programming based on WINDOWS, fast and convenient

programming, and visual previewing.8. Drilling units equip with

famous brand spindle motor.9. The key mechanical, hydraulic and

electric parts are all famous brands. Machine

DetailApplication:The SWZ1000C three-dimensional CNC drilling

machine production line is composed of SWZ1000C three-dimensional

CNC drilling machine, feeding trolley and material channel. It can

be widely used in steel structure industries such as construction,

bridges, power station boilers, three-dimensional garages, offshore

oil well platforms, tower masts, etc.Packaging & Shipping Our

AdvantagesProfessional Technical Team: We own a

professional technical team who devote to the advanced design on

the machines and better performance with plenty experience more

than 15 years.Various Patents: we have been got many patents

on various models of our products these years and keep on

developing new products.High Products Quality:We have been gained a

lot of good reputation among our customers and never got any

quality complaint until now Professional Experienced

Sales Team:Our sales team have average 10 years ' experience

in export process, they are qualified to provide the most

reasonable proposal for you and resolve your problems on machines

selection and usage immediately once you ask.FAQ1. What's your

advantage ?A: We assure each machine dispatched from our factory a

long-life usage with easy operation and humane design.We consider

help our customer to hence the production efficiency and save your

human power as our aim.2. How l believe you?A: Welcome to visit us

to check our plant and ability, the payment method can be

chosen and the third party inspection through

Alibaba is available.3. What about the warranty of your

products?A: We provide 12 months warranty since the machine arrived

at customer site , free charge of spare parts and oline

maintenance service4. Where are you? Can l visit you?A: our factory

located in Shandong province, china, welcome to visit us at any

time.5. How about the delivery time?A: For standard model, the

delivery usually 25 days since the advance payment receipt. For the

customized products, the delivery time will follow our agreement

with customer.We never receive any complain from our customers for

the delivery time6. What kind of payment does your company

support?A: TT,100% LIC at sight,Cash, Western Union are

accepted. If you have other payment terms, welcome discuss with

usOur Service1. OEM DESIGN AND PRODUCTION:Our active engineer

and design team can make the special machine according to

Related products about Heavy Structural Fabrication 3D Drilling Machine for H Beam Steel

-

Metal Sheet Cutting Machine Steel Coil Processing Line Cut to Length Line

Metal Sheet Cutting Machine Steel Coil Processing Line Cut to Length Line

-

Metal Sheet Cutting Machine Steel Coil Processing Line Cut to Length Line

Metal Sheet Cutting Machine Steel Coil Processing Line Cut to Length Line

-

Best Selling Solar Strut Channel Profile Steel Roll Forming Machine

Best Selling Solar Strut Channel Profile Steel Roll Forming Machine

-

Best Selling Solar Strut Channel Profile Steel Roll Forming Machine

Best Selling Solar Strut Channel Profile Steel Roll Forming Machine

-

New CNC Machining Angle Steel Punching Shearing Marking Machine for Steel Structure

New CNC Machining Angle Steel Punching Shearing Marking Machine for Steel Structure

-

New CNC Machining Angle Steel Punching Shearing Marking Machine for Steel Structure

New CNC Machining Angle Steel Punching Shearing Marking Machine for Steel Structure

-

High Speed Beam Drilling CNC Plannar Drilling Machine for Metal Steel

High Speed Beam Drilling CNC Plannar Drilling Machine for Metal Steel

-

Best Selling Manufacturer CNC Drilling Machine for Steel Plate

Best Selling Manufacturer CNC Drilling Machine for Steel Plate