Rubber Powder Production Line/Rubber Tire Crusher1.Automatic

Production Line ProcessWaste Tires-→Single Hook Debeader-→Tire

Cutter-→Whole Tire Shredder-→Rubber Crusher -→Oscillating Screen,

Conveyor Belt, Magnetic Plants-→Fiber Separator -→Fine Rubber

Powder Pulverizer-→Rubber Powder 2.Semi-Automatic Production Line

ProcessWaste Tires-→Ring Cutter-→Press loop Machine-→Strips

Cutter-→Blocks Cutter-→Rubber Crusher -→Oscillating Screen,

Conveyor Belt, Magnetic Plants-→Fiber Separator -→Fine Rubber

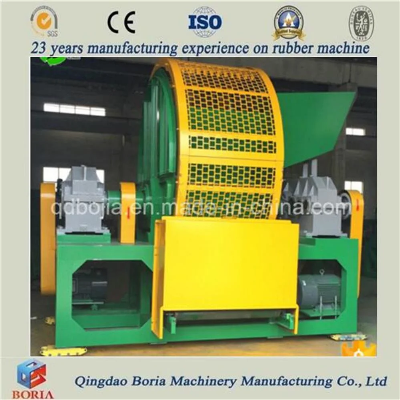

Powder Pulverizer-→Rubber Powder Rubber Crusher ( It will be chosen

according to your need capacity) 1. This Rubber machine is used for

crushing rubber and plastic. The roll made of alloy chilled cast

iron is better than those of common chilled cast iron. 2. The

interior of the two rolls is empty and spray type. The temperature

of roll surface is even. 3. To assure the safety, we install

emergency pulling up equipment. Convenient range adjustment is set

in manually operation. The safety shut down in manual operation is

set, with the function of automatic crawl back swing the roll. 4.

Convenient range adjustment is set in manually operation. The whole

machine adopts channel-bottom head for convenient carrying and

maintance. 3.The Rubber Powder has more Applications, please refer

to the below introduce:5-10 mesh: runway, school playgrounds,

garden paths, bowling alleys, sidewalks, composite rubber floor

tiles, anti-static floor tiles, artificial turf, playground,

artificial turf soccer field the the kindergarten sports venues and

casino tennis and basketball courts. 10-20 mesh: rubber floor

tiles, plastic runway, lawn quartz sand, cottonseed husk pellet,

tennis courts, volleyball courts, a golf course, aircraft pitch,

basketball court and recreational field, EPDM safety mats, gym

mats, all kinds of The stadium floor mats. 30 mesh: plastic

insulation material, waterproof material, shockproof, washers, roof

and wall waterproofing membrane, modified bitumen additives,

reclaimed rubber, livestock, straw mats, fender, multifunctional

mat, stable mat. 40 mesh: reclaimed rubber waterproofing membrane,

modified bitumen additives, carpet padding, sleepers, rubber sheet,

livestock grass mats, rubber water-stop gate waterstops, bearings,

seal, buffer, brake brake linings cover, drainage pipes, gloves,

rubber bands, elastic band, roof signs, brick material top liner,

sanitary pumps, corner glue, wheel alignment, the pump pumping sand

pads, fenders, multi-function pad, stables pad, resistance burning

material, sound insulation materials, rubber and rubber-soled,

window sealing strip of rubber products and agricultural Oaks

(milk) Polystyrene. 60 mesh: sleepers, rubber sheet, waterproofing

membrane, reclaimed rubber, tire inner cushion, car underbody

sealed, waterproof ring, rubber miscellaneous pieces the

alternative native gum production of rubber products. 80 mesh:

modified asphalt additives, reclaimed rubber, waterproof membrane,

the size of the tire additives, sleepers, deceleration road humps,

sealing strips, buffer, styrofoam pearls pad, rubber products,

rubber piston, brake gate bushing. 100 mesh: automotive bias tires

auxiliary specialized packing of materials, footwear, sports

equipment tires. 120 mesh: plastic pipe insulation material

additives, automotive bias tires auxiliary materials, car

refurbished outside pad, dedicated shoe filler, chemical sealant

various rubber seepage mixtures. 200 mesh: building material

coatings, automobile tires, and alternative raw rubber production

of various rubber products. Technical parameter

TypeXKP-400XKP-450XKP-560Front roll diameter(mm)400450560Rear roll

diameter(mm)400(Groove roller)450(Groove roller)510(Groove

roller)Working length of rolls(mm)600650800Front roll surface

speed(m/min)17.3223.225.56Friction ratio1: 1.381: 1.381: 1.4.Our

machine listOur company professional manufacture rubber vulcanizing

press (frame type,four column type,lab press and so on), rubber

mixing mill, batch off cooler, rubber extruder, rubber strip making

machine and tire recycling equipment.5. Our service1. Our engineers

can design target machines for customers and send them the drawing

to confirm. We are always on the side of saving your

cost.2. In the process of production, we will take photos and

send to customers for their track the progress.3. Documents

such as packing list, commercial invoice, and bill of lading etc.

will be sent after the delivery.4. We could supply free

English foundation DWG, installation drawing, user guide,

maintenance manual and part drawing.5. We supply overseas

engineer service and help to train your workers to operate the

machine.6. Test running: The above machines are all passed

inspection of 3~5 hours of full load operation before leaving our

factory. And we will take the video and send it to you for

inspection. You can use it directly thus saving the time of

test-run and expense. And we also warmly welcome to our factory to

inspect and test running.7.Warranty: 12 mon

Related products about Rubber Oil Refining Machine and Waste Tire Recycling Machine

-

Xk-400 Open Type Rubber Mixing Mill with Stock Blender

Xk-400 Open Type Rubber Mixing Mill with Stock Blender

-

Xk-400 Open Type Rubber Mixing Mill with Stock Blender

Xk-400 Open Type Rubber Mixing Mill with Stock Blender

-

Boria Customized Rubber Bucket Elevator for Rubber Batch Lifting Hoist

Boria Customized Rubber Bucket Elevator for Rubber Batch Lifting Hoist

-

35L-110L Kneader Rubber Compound Lifting Bucket Elevator

35L-110L Kneader Rubber Compound Lifting Bucket Elevator

-

Direct Manufacturer Silicone Rubber Mixing Mill/ EPDM Rubber Mixer Machine/ SBR Lab/Laboratory Two Roll Mills/ NBR Open Mill with Stock Blender Xk400/450/560

Direct Manufacturer Silicone Rubber Mixing Mill/ EPDM Rubber Mixer Machine/ SBR Lab/Laboratory Two Roll Mills/ NBR Open Mill with Stock Blender Xk400/450/560

-

Factory Price Two Roll Open Rubber Mixing Mill, Rubber Roller Mixing Mill, Lab/Laboratory Rubber Mixing Machine Mixer Mill (6/10/12/14/16/18/22/26/28 inch)

Factory Price Two Roll Open Rubber Mixing Mill, Rubber Roller Mixing Mill, Lab/Laboratory Rubber Mixing Machine Mixer Mill (6/10/12/14/16/18/22/26/28 inch)

-

Factory Price Two Roll Open Rubber Mixing Mill, Rubber Roller Mixing Mill, Lab/Laboratory Rubber Mixing Machine Mixer Mill (6/10/12/14/16/18/22/26/28 inch)

Factory Price Two Roll Open Rubber Mixing Mill, Rubber Roller Mixing Mill, Lab/Laboratory Rubber Mixing Machine Mixer Mill (6/10/12/14/16/18/22/26/28 inch)

-

Direct Manufacturer Silicone Rubber Mixing Mill/ EPDM Rubber Mixer Machine/ SBR Lab/Laboratory Two Roll Mills/ NBR Open Mill with Stock Blender Xk400/450/560

Direct Manufacturer Silicone Rubber Mixing Mill/ EPDM Rubber Mixer Machine/ SBR Lab/Laboratory Two Roll Mills/ NBR Open Mill with Stock Blender Xk400/450/560