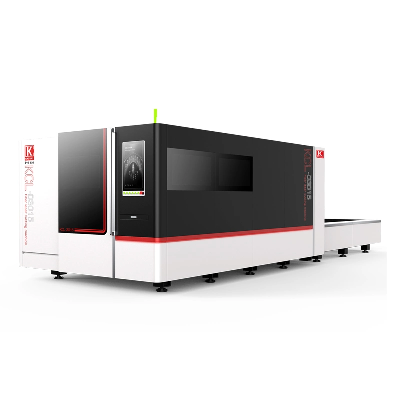

Products DescriptionPerformance.The new closed design, fast

exchange of double worktables, cutting while processing, high

speed, small cutting seam, smooth section, simple operation and low

energy consumption. It is suitable for mass continuous processing

and highlights the cutting competitive advantage.Safety protection,

pollution-free, fully enclosed and enclosed design, protected by

European CE standard protective glass, internal filteringtreatment

of cutting smoke and dust, up to standard discharge and no

pollution.For more details, please click here.>>>Details

ImagesModelKCL-D3015KCL-D4015KCL-D4020KCL-D6020KCL-D6025KCL-D8025KCL-D10025KCL-D12025Cutting

Range

(mm)3000*15004000*15004000*20006000*20006000*25008000*250010000*250012000*2500Laser

Power

(w)1000W&1500W&2000W&3000W&6000W&8000W&12000WMaximum

idle speed160 m/minMaximum cutting speed35-80 m/minPositioning

Accuracy0.03 mmReposition Accuracy0.02 mmFor more parameter

details, please click here.>>>Core ThechnologyMAX & Raycus

& IPG Brand Laser SourceHigher Electro-optic conversion efficiency

Superior reliability & modularity Easy maintenance and low down

time Anti high reflection functionLaser Cutting head3 pieces of

protection lens, highly effective protection of collimating focus

lens. 2-way optical water cooling, effectivelyextending the

continuous working time.Various brands of laser head are

available CYPCUTEasy to useVanous file editing

functionsSupporl remole oontrolReal-time alarm and protection Steel

Plate Welding steel frames undergo annealing at over

600 degree to relieve stress. They are built to last years of

heavy use without distortion. Autochanging pallet system allows

over 1800kg loading weight.A heavier frame means less vibration and

better accuracy. the machineframes are reinforced to minimize

twists and deformation while the robust frame of the machine is

joined to the chassis by steelbars. Aluminum beamThe beam

body adopts the overall aluminum casting method, annealing

eliminates internal stress and processes, The process iscasting

→annealing stress → rough machining → vibration aging →

semifinishing → vibration aging →finish machining, the machine is

machined after tempering, the strength, rigidity and stability of

the beam are guaranteed, the precision of the beam can bemaintained

for a long time. Mainly for the high speed cutting of high power

laser cutting machine provides an effective guarantee. For

more details, please click here.>>>France

MOTOREDUCER

Servo Motor-Japan

FUJIHanli brand Industrial chiller

Touch screenAir Compressor(Optional)

Volatge Regulator(Optional)

Dust Extraction System(Optional)Cutting Thickness of Fiber

Laser Cutting MachineInquiry right now.>>>Cutting

SamplesCompany & Factory IntroductionLearn more about our

company.>>>Get latest shipping price, please click

here.>>>Our ServicePre-sales services:1. inquiry and

consulting support 2. sample testing support 3. visit our

factory After-sales

services: 1.

2 years warranty

period 2.

training how to install and use the

machine 3.

engineers available to service machinery

overseas Contact

Ways Mr.Pumbaa Yang Customer Manager E-mail:pumbaa@jinqiu.cc

FAQ1.Can you supply the relevant documentation?Yes, we can

provide most documentation including Certificates of

Analysis/Conformance; Insurance; Origin, and other export documents

where required.2.What is the average lead time?For samples, the

lead time is about 7 days.For mass production, the lead time

is 20-30 days after receiving the deposit payment.The lead times

become effective when (1) we have received your deposit, and (2) we

have your final approval for your products. If our lead times

do not work with your deadline, please go over your requirements

with your sale. In all cases we will try toaccommodate your needs.

In most cases we are able to do so.3.What kinds of payment methods

do you accept?You can make the payment to our bank account, Western

Union or PayPal:30% deposit in advance, 70% balance against the

copy of B/L.Or irrevocable LC at sight.4.What is the product

warranty?We warranty our materials and workmanship.Our commitment

is to your satisfaction with our products. In warranty or not, it

is theculture of our company to address and resolve all customer

issues to everyone's satisfaction.5.Do you guarantee safe and

secure delivery of prod

Related products about Kcl Mini 1kw 2kw 3kw 4kw 6kw 8kw 12kw 20kw Mild Stainless Steel Iron Aluminum Copper CNC Sheet Metal Tube Pipe CNC Automatic Fiber Laser Cutting Machine

-

100 Ton 4 Column Hydraulic Press Deep Drawing Press with Factory Price

100 Ton 4 Column Hydraulic Press Deep Drawing Press with Factory Price

-

100 Ton 4 Column Hydraulic Press Deep Drawing Press with Factory Price

100 Ton 4 Column Hydraulic Press Deep Drawing Press with Factory Price

-

QC11y-20X5000 Stainless Steel Hydraulic Guillotine Plate Sheet Scrap Metal CNC QC11K 8mm Shearing Cutting Machine 4000 mm

QC11y-20X5000 Stainless Steel Hydraulic Guillotine Plate Sheet Scrap Metal CNC QC11K 8mm Shearing Cutting Machine 4000 mm

-

QC11y-20X5000 Stainless Steel Hydraulic Guillotine Plate Sheet Scrap Metal CNC QC11K 8mm Shearing Cutting Machine 4000 mm

QC11y-20X5000 Stainless Steel Hydraulic Guillotine Plate Sheet Scrap Metal CNC QC11K 8mm Shearing Cutting Machine 4000 mm

-

2021 Hot Sale 1000 Ton Hydraulic Press Cylinder or 500 Tons Power Press

2021 Hot Sale 1000 Ton Hydraulic Press Cylinder or 500 Tons Power Press

-

3200mm Kingball Blade QC12y Series Simple CNC Shearing Machine.

3200mm Kingball Blade QC12y Series Simple CNC Shearing Machine.

-

3200mm Kingball Blade QC12y Series Simple CNC Shearing Machine.

3200mm Kingball Blade QC12y Series Simple CNC Shearing Machine.

-

Kcl Mini 1kw 2kw 3kw 4kw 6kw 8kw 12kw 20kw Mild Stainless Steel Iron Aluminum Copper CNC Sheet Metal Tube Pipe CNC Automatic Fiber Laser Cutting Machine

Kcl Mini 1kw 2kw 3kw 4kw 6kw 8kw 12kw 20kw Mild Stainless Steel Iron Aluminum Copper CNC Sheet Metal Tube Pipe CNC Automatic Fiber Laser Cutting Machine